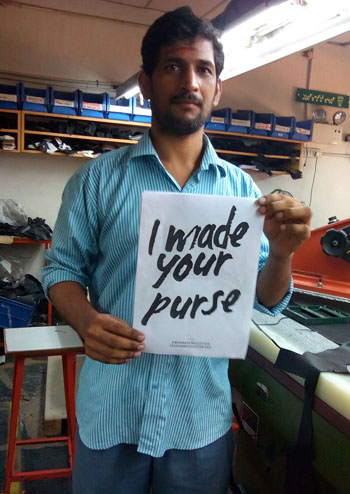

This is Narashiman our head leather cutter at the workshop in rural India where all my designs are made.

This is Narashiman our head leather cutter at the workshop in rural India where all my designs are made.

Cutting the leather pattern pieces for all the different designs is a very skilled job because every skin needs to be inspected to make sure there aren’t any flaws in the leather.

Once a new design goes into production most pieces are cut using a die or knife which is made in metal to the exact shape of the pattern required. These dies have super sharp knife edges which slice through the leather when force is applied by the top part of the hydraulic cutting table being lowered down onto the die or knife. As you can imagine it can get quite noisy with all the cutting machines in action, so the cutters have their own room, away from the rest of the workers who stitch and hand assemble the bags and wallets.

Narashiman is 36 years old and he lives in the local village with his wife, Indumathi and their daughter who is 7 and son who is 2. He’s worked with us for 4 years now and is really glad he moved into our industry from the electronics parts business where he used to work.

Here is Narashiman inspecting the leather. He keeps a few of the cutting dies on the table close to hand so that he can make best use of the leather by cutting larger pieces followed by smaller pieces as the skin gets smaller.

Here is Narashiman inspecting the leather. He keeps a few of the cutting dies on the table close to hand so that he can make best use of the leather by cutting larger pieces followed by smaller pieces as the skin gets smaller.

Having cut just one largish piece, Narashiman moves the knife swiftly across to another part of the leather skin to cut the same part again.

Having cut just one largish piece, Narashiman moves the knife swiftly across to another part of the leather skin to cut the same part again.

Two hands are then needed to move the cutting press across and down to stamp out another pattern piece.

Two hands are then needed to move the cutting press across and down to stamp out another pattern piece.

So that’s an introduction to Narashiman and the work he does for us.

Nandrie (thanks) Narashiman!

Meet our other highly skilled workshop staff here.

Great insight into Indian production thanks

Thanks Honey. Sadly it’s not always so good. It pays to find out where your purchases are made and only buy from companies with ethical production.

If you want to know more – take a look at http://www.fashionrevolution.org

🙂

Thank you for broadening my horizons today great to see how industry works in another country and also seeing a human and friendly side of the business

Thanks for your comments Elaine

What a great idea to introduce someone from your team in India, well done on fully appreciating them

They are all great Mike. I love going out there to see how they’re getting on.